Pharmaceuticals, feeds, food stuffs, pigments, mixing.

|

Moadel

|

NM

-10 |

NM

-15 |

NM

-20 |

NM

-30 |

NM

-40 |

NM

-50 |

NM

-60 |

NM

-70 |

NM

-80 |

NM

-100 |

|

|

Volume

|

1000

|

1500

|

2000

|

3000

|

4000

|

5000

|

6000

|

7000

|

8000

|

10000

|

|

|

Main

Motor

|

5

|

7

1/2

|

7

1/2

|

7

1/2

|

10

|

15

|

20

|

20

|

25

|

30

|

|

|

Sub.

Motor

|

-

|

-

|

-

|

-

|

2

|

2

|

2

|

2

|

2

|

2

|

|

|

R.P.M

|

60

|

60

|

60

|

60

|

60

|

60

|

60

|

60

|

60

|

60

|

|

|

R.P.M

|

2

|

2

|

2

|

1.5

|

1.5

|

1.5

|

1.5

|

1.5

|

1.5

|

1.5

|

|

|

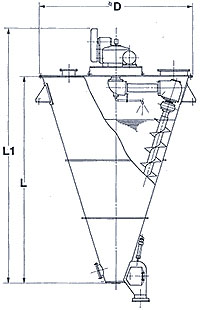

Diameter*D

|

1758

|

1978

|

2130

|

2412

|

2819

|

2977

|

3119

|

3246

|

3364

|

3568

|

|

|

(Container

Hight) L

|

2258

|

2595

|

2845

|

3260

|

3905

|

4165

|

4395

|

4605

|

6100

|

5130

|

|

|

(Full

Hight) L1

|

3265

|

3630

|

3880

|

4300

|

5205

|

5465

|

5695

|

5905

|

4800

|

6430

|

|

|

(Weight)

Kg

|

1150

|

1250

|

1350

|

1500

|

2700

|

2900

|

3100

|

3300

|

3500

|

3900

|

|